High Gas Turbine-Generator Vibration GE Frame-9

- Nitheesh Abdul Rahman

- Sep 9, 2024

- 2 min read

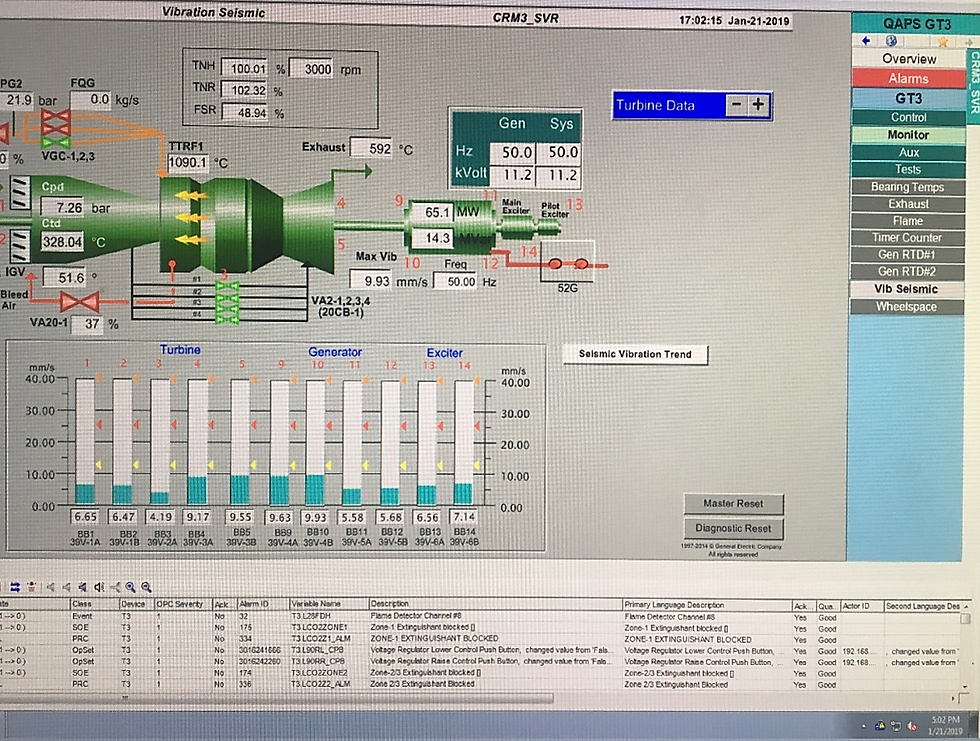

A power generation company in Oman was facing high vibration issue in one of the GTs. At Full Load of around 100 MW, the turbine was vibrating at 9.63 mm/s PK (velocity sensors). This is near the set alarm of 11 mm/s PK, and there was a chance vibration would increase during peak summer.

SITE CONDITIONS

• The machine train consists of a generator (120MW Base load capacity) Turbine and Generator operating at 3000rpm. The GT is mounted on a concrete foundation.

• High vibration was observed mainly on Generator DE (Bearing 5).

• Major overhauling was done on the Turbine (Not Generator) three months ago.

• No proximity sensors available.

OBSERVATIONS

• The initial data were taken on the Generator NDE and DE show dominant 1X and minor 2X.

• The higher-than-normal 1X is due to unbalance force on the Generator.

• Other bearings showed normal 1X within acceptable limits.

• The run-up data of B3 and Generator DE Shows two critical speeds, 1st at 1,100 RPM and 2nd at 2,108 RPM.

DIAGNOSIS

• Since the high vibration was observed at 1X speed with a phase angle of 114 Degrees (Vertical to Horizontal), the cause of the high vibration on the Generator was identified to be caused by unbalance.

• On-site balancing could be done to reduce the vibrations.

ACTION PLAN:

Inspect the Generator rotor.

Carry out on-site dynamic balancing.

MAINTENANCE:

• Inspection of the generator rotor revealed a high quantity of dust deposition on the rotor.

• The dust had solidified on the rotor and could not be easily removed.

• Since the tools were not available for proper cleaning at the site, it was decided to carry out dynamic balancing as a short-term solution.

• All the air inlets and filters were checked and minor faults were corrected. Some leaks in the filter house were also fixed.

ACTION:

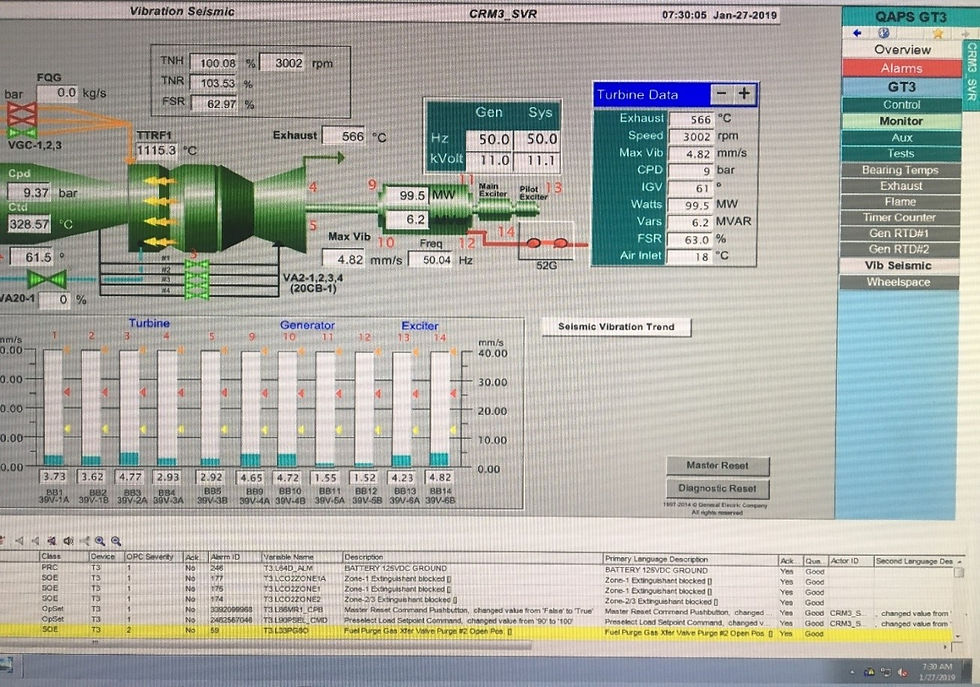

• On-site dynamic balancing was carried out to reduce the vibrations significantly

• Preventive measures taken to prevent further dust deposition.

• A plan was put in place to clean the rotor during the next outage (will require removal of old balancing weights after)

Comments